Properties of wool

Wool has been a precious raw material for people for a long time. Yarns have been spun out of wool fibres for several millenniums. As the range of available fibres was limited in the past, wool used to be a very valuable commodity.

Today we are able to select between a huge variety of fibres with varying properties, but nevertheless, the percentage of wool in fibre production all over the world averaged out 2 % in 2005. This corresponds to around 1.2 million tons of wool every year of which about 75 % is used in the clothing industry.

T he continuing use of wool – in spite of the competition with other natural fibres and new synthetic fibres – for suits, coats and pullovers can be attributed to the unique properties of wool:

- thermal regulative due to high amounts of air embedded in the fibre

- high absorption of moisture

- low tendency to creasing

- low flammability

However, wool has not just got properties which offer high wearing comfort. A big disadvantage, which emerges during washing, is the felting tendency.

Knitwear made of unfinished wool prior to and after washing

Why does wool felt?

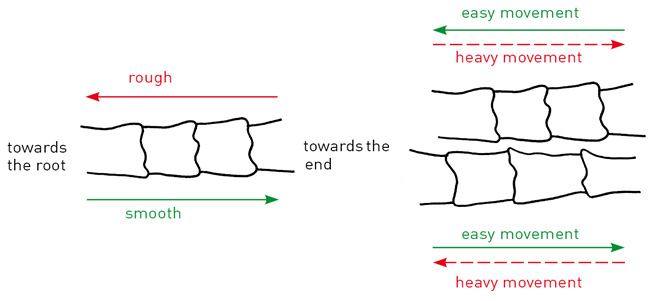

Under the influence of warm, alkaline water, the scales surrounding the wool fibres rise. If the wool fibres are additionally moved, the fibres wedge with each other more and more since they can only glide in one direction due to the scales. The fabric shrinks and gets tighter.

Methods for Antifeltlt Finishing

To prevent felting of wool and to make wool washable in normal household washing machines, several methods have been developed:

- softening /removing of scales by chemical modifications (oxidation)

- covering of scales by application of a resin

- combination of oxidation and enzymes

- plasma treatment

- combination of removal and covering(so called Chlor-Hercosett-process)

- Petry-Lanazym-process

In contrast to the less effective single treatments, the combination of oxidation and enzyme as well as the technically demanding plasma treatment, the Chlor-Hercosett-process has a very good cost-value ratio.

However, if the antifelt properties are sufficient for a washing with a wool wash programme at 40 °C , the Petry-Lanazym-process is an interesting, ecological alternative for Chlor-Hercosett-process.

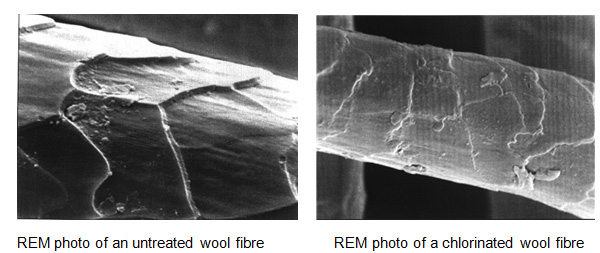

Chlor-Hercosett -process

In this process, the first step is to remove the scales of the wool fibres’ surface using a strongly acid chlorine and subsequent sulphite treatment. In the second step, a polymer resin is applied. Both processes lead to a strong smoothening of the fibre surface in which the fibres are able to glide off each other and the felting tendency is strongly decreased.

Due to its various advantages, the Chlor-Hercosett-treatment is the most frequently used process in industry today:

- excellent antifelt effects and super-wash achievable

- low damaging of wool and little loss of weight

- improved dyeability

- improved pilling behaviour

N evertheless, there are also some disadvantages to the Chlor-Hercosett-process:

Textile aspects

- loss of natural wool character

- synthetic handle

- yellowing of wool

Ecological aspects

- AOX pollution of waste water

- biodegradability of fabric is affected

With the Chlor-Hercosett-process, a very good antifelt effect can be achieved. On the other hand, significant environmental influences are also involved.q

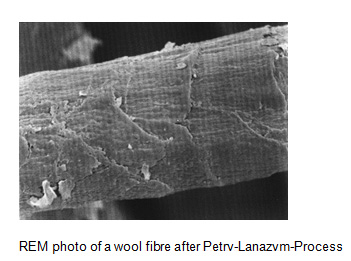

PETRY-LANAZYM-PROCESS

With the single-step Petry-Lanazym-process, the scales of the wool are partially degraded – as in Chlor-Hercosett-process. The result is a smoother surface structure which facilitates the sliding of wool fibres in both directions and decreases felting tendency that way.

The Petry-Lanazym-finishing offers the following advantages:

Textile aspects

- wool can be washed with wool washing programme up to 40 °C

- maintaining of natural wool character

- low yellowing

- increased dyeability (similar to Chlor-Hercosett-process)

- improved pilling behaviour

Ecological aspects

- no chlorine

- no ?heavy“ chemistry

- no problems with disposal of fabrics

- compatible with Oeko-Tex and GOTS guidelines

O f course, there are limits to the Lanazym treatment as far as the antifelt effects are concerned. This can especially be seen in the case of high stressing of the fabric. In comparison to wool treated by Chlor-Hercosett-process, the shrinkage of enzymatically treated wool is distinctly higher when it is washed under strong mechanical stress (for example DIN EN 26330-5A). However, if the fabric is washed with a wool washing programme – as customers usually do – the shrinkage of chlorinated wool and wool treated in the eco-friendly Lanazym-process is comparable.

The Petry-Lanazym-treatment can be processed in normal finishing machines and has already been used for antifelt finishing of wool yarns in discontinuous processes since 1998.

If you are interested in further information or concrete product proposals for our Petry-Lanazym-process, just let us know.