Infrared needle temperature measurementContact-free infrared needle temperature measurement on

high-speed industrial sewing machines A milestone for the development of modern highly efficient sewing thread lubricants

INTRODUCTION

For more than 30 years TEXTILCHEMIE DR. PETRY GMBH have been engaged in the development and manufacture of high-class lubricants for sewing threads and embroidery yarns.

In our modern equipped laboratories we are working on the further development of our products.

Our laboratories

In collaboration with our customers we develop tailor-made, high-quality and cost-effective solutions for a wide range of applications.

While developing such products it is essential to have reliable and reproducible test methods.

For sewing thread typical properties such as friction value, stick-slip,

antistatic, abrasion, etc., we have approved and internationally accepted test methods which have been available for many years and allow reliable evaluation of the yarn properties.

The heat resistance of yarns during the sewing process is an exception. For many years attempts have been made to ?measure“ the heat protection of yarns during sewing. However, all applied tests are based on the ultimate failure of the yarn.

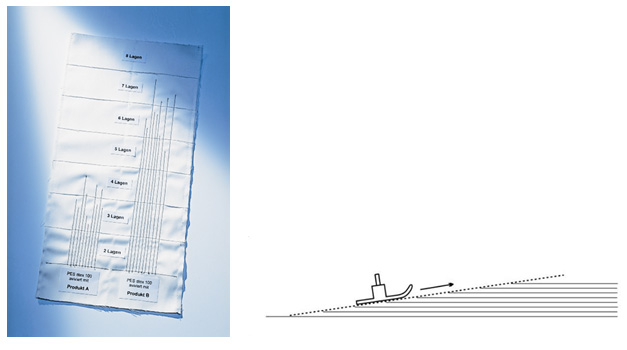

This means that by increasing the number of layers, variation of the

thread tension and/or by an 別ndless?extension of the thread distance the sewing conditions are brought to a limit until a failure occurs (breaking or

melting). The most common of these methods involves sewing multiple layers of fabric.

Such worst-case tests, however, give very conditional information about the real performance of a yarn.

Furthermore, the reproducibility of such sewing results is not satisfying. Informative statistical results can only be achieved by carrying out a large number of tests. For development work in a textile-chemical laboratory such rough tests do not really lead to a successful conclusion.

In search of a modern, reliable and significant test method for the heat protection properties of sewing threads we finally came to the infrared measurement. During an ambitious two-year industrial research project in co-operation with the Institute for Textile and Process Engineering,

Denkendorf (ITV) we have found a solution and now have a reliable

measurement technique.

MEASUREMENT TECHNIQUE

The idea to measure needle temperatures contact-free via infrared is not new. Literature investigations have shown that in the 70‘s trials in this respect were made. From our customers we know that individual companies have created their own measurement techniques using

infrared measurement. A disadvantage of these measurement

methods is the lack of a suitable calibration technique. Hence, the

temperature can only be measured roughly. The aim of our measurement

technique, however, was to achieve a reliable, reproducible and exact measurement for the textile-relevant temperature range of 100 – 350 °C.

For this the selection of a suitable pyrometer with a respective sensitivity, small measuring spot and short measuring frequency was the first precondition.

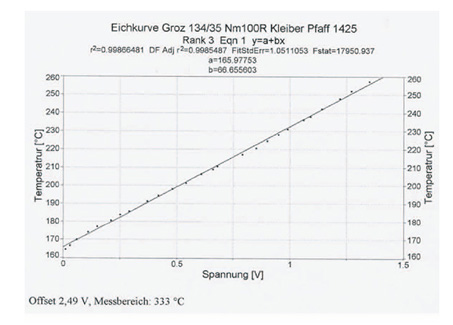

Secondly, one had to succeed in creating a calibration device, which allows a reliable assignment of the measured values of the pyrometer to the temperature.

Calibration curve

Finally, it must be possible to output these values and to evaluate them by means of a modern data processing. For this task a suitable software had to be developed and adapted.

We have reached all these targets in the frame of industrial research and have set up a measuring unit, that we have made intensive use of during the past 12 months. To come straight to the point: we are very excited about the possibilities of this new measurement technique.

Alignment of the measuring device (industrial sewing machine, special-IR-camera)

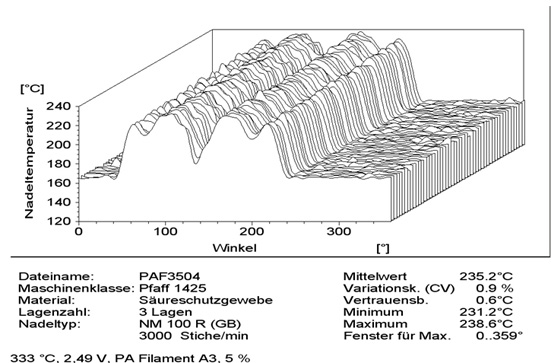

At a sewing speed of 2500 rpm the pyrometer offers us 667 measuring values per second or 16 measuring values per needle penetration.

Within this measuring frequency of only 1.5 ms and a sensitivity range of

100 – 350 °C this pyrometer offers best preconditions for reliable

measurement and will even show the precise differences in temperature along the needle length.

Multiple values are recorded during the measuring process. For example during a sewing process of 400 stitches, the pyrometer returns 6400

individual values. All this data comes from an operation that takes less than 10 seconds. This mass of data can then be statistically evaluated via the software. Our intensive test of the measuring technique has shown that we can achieve very precise and easily reproducible results.

Detailed measuring value diagram

BENEFIT

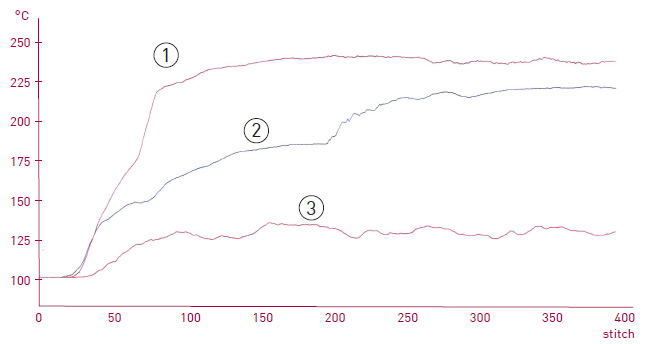

This new measurement technique allows for precise demonstration of the actual temperature profile during a sewing process.

1. Sewing without yarn

2. Sewing with yarn, not lubricated

3. Sewing with yarn, finished with 4 % PERIXEN SLH

For the first time in the history of sewing thread analysis this measuring unit offers the possibility to precisely record and evaluate the actual

temperature behaviour of the sewing needle during a sewing process. We do not believe it to be exaggerating if we consider this as a milestone

for the further development of modern, highly efficient sewing thread

lubricants.

We have made extensive laboratory studies in order to examine the

influence of the chemistry and the layer of different lubricants on different sewing threads.

The results are highly interesting and offer unforeseen possibilities for the optimisation and further development of our products. The experiences gathered so far have already led to the development of products that would not have been possible without this new measurement technique.

For our customers this new measurement technique shows an invaluable advantage, too:

For the first time it is possible to make an objective comparison of the

sewing properties from a competitor‘s yarn and lubricant.

Existing lubricating processes can be checked and evaluated. An individual study of a customer‘s yarn allows for optimisation of the chemistry and the layer of the lubricant and thus saving potentials can be identified.

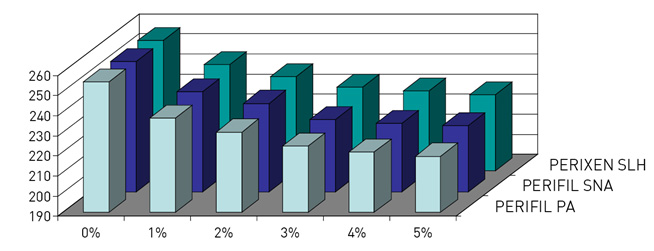

Average needle temperature with high tenacity PES-filament yarn depending on product and layer:

Chemistry and layer influence the heat protection

SHAPING THE FUTURE

With our new technique for the online needle temperature measurement a new era in the evaluation of thermal influences on the sewing processes begins.

As a partner of the textile industry we are pleased to take up the challenges arising in the market and find tailor-made solutions for our customers.

We invite you to work together with us in the further development of lubricants and processes.

Should you have any questions or you would like to work with us on an actual production problem our sewing thread experts would be pleased to offer you the necessary technical assistance.